LBO – Nonlinear crystal

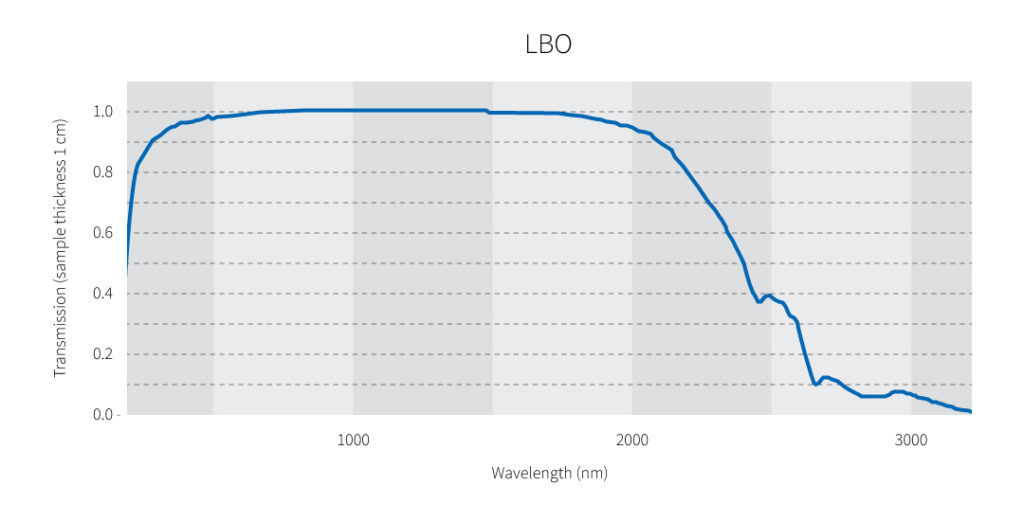

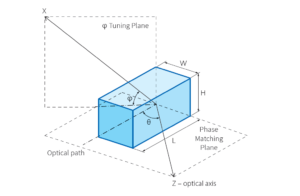

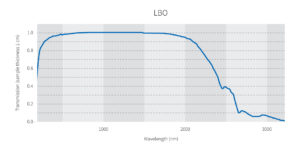

LBO (LiB3O5) crystal is first picked among other non-linear crystals used to produce high power second and third harmonic laser light. Large band gap and transparency region, high non-linear coupling, good chemical and mechanical properties make this crystal capable of optical parametric processes (OPO/OPA) and noncritical phase matching (NCPM), too.

Features:

- Broad transparency range from 160 nm to 2.6 µm

- High optical homogeneity

- Relatively large effective SHG coefficient (about three times that of KDP)

- 554 nm – 2.6 µm phase matching range for Type I SHG

- 790 nm – 2.15 µm phase matching range for Type II SHG

- Small angular SHG walk-off at room temperature, no NCPM walk-off at 149 °C

- Wide acceptance angle

Contact us for more information: [email protected]

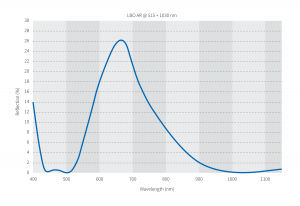

Comparison of bulk damage threshold (@1064 nm, 1.3 ns)

| Crystal |

Energy fluence (J/cm²) |

Power density (GW/cm²) |

| KTP |

6.0 |

4.6 |

| KDP |

10.9 |

8.4 |

| BBO |

12.9 |

9.9 |

| LBO |

24.6 |

18.9 |

Applications:

- Either Type I or Type II frequency doubling (SHG) and sum frequency generation (SFG) of high peak power Neodymiun-doped , Ti:Sapphire, Alexandrite and Cr:LiSAF lasers

- Temperature-controllable non-critical phase matching (NCPM) for 1.0–1.3 µm

- Room temperature NCPM for Type II SHG at 0.8–1.1 µm

- Widely tunable OPO/OPA for both Type I and Type II phase matching

Application notes:

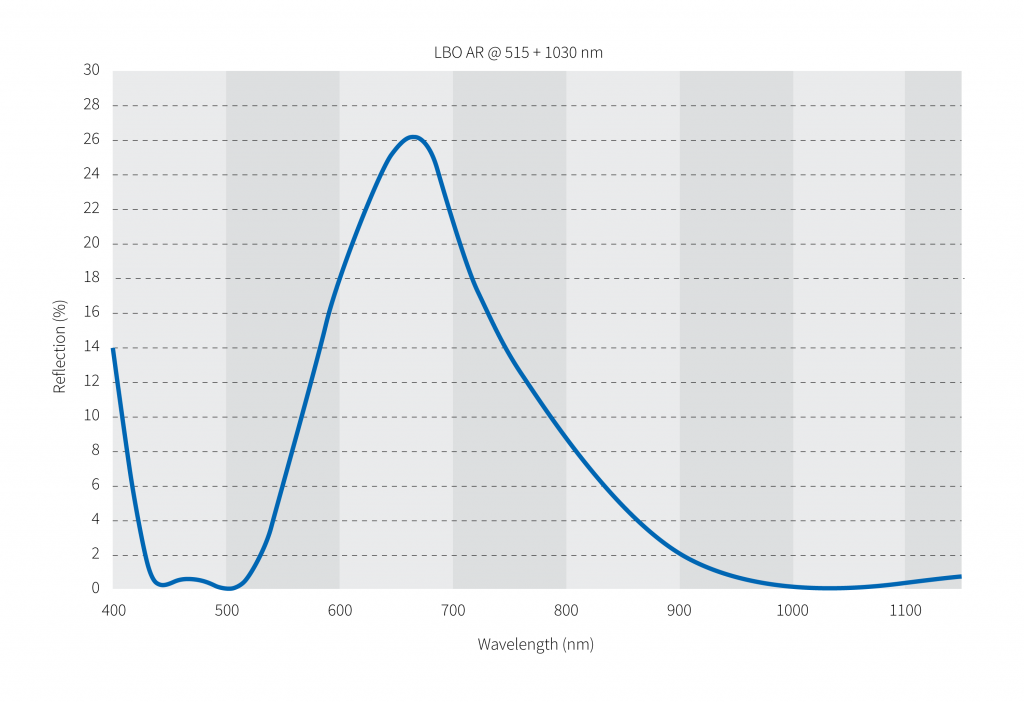

- Available coatings

- Multi-layer dielectric laser line, dual-band or broad-band AR coatings

- Single-layer protective coatings (P-coating)

- Brewster cut

- LBO crystals with one or both Brewster cut ends for high-power applications are available upon request. Such configuration minimizes Fresnel losses without a reduction of surface damage threshold.

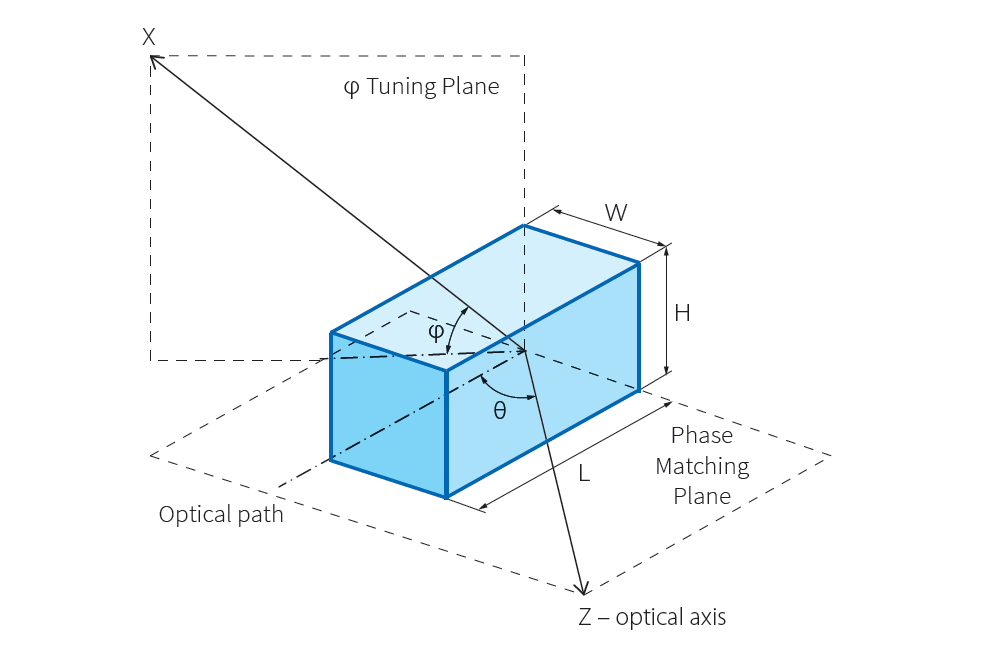

Recommended LBO crystal length (mm)

| Application (T = 300 K) \ Pulse duration, fs |

10 |

50 |

100 |

150 |

300 |

| SHG @ 1030 nm, Type I, Ɵ=90°, Φ=13.6° |

0.1 |

0.9 |

1.8 |

2.8 |

5.6 |

Typical Items

LBO crystals for Nd:YAG lasers

Clear Aperture, mm |

Length, mm |

Orientation Θ/φ, ° |

AR coatings S1/S2, nm |

Application |

Product ID |

| 3x3 |

10 |

42.2/90 |

1064+532/355 |

THG @ 1064 nm, Type II |

4-LBO-3310-0 |

|

|

90/11.6 |

1064+532/1064+532 |

SHG @ 1064 nm, Type I |

4-LBO-3310-1 |

| 3x3 |

15 |

42.2/90 |

1064+532/355 |

THG @ 1064 nm, Type II |

4-LBO-3315-0 |

|

|

90/11.6 |

1064+532/1064+532 |

SHG @ 1064 nm, Type I |

4-LBO-3315-1 |

| 3x3 |

15 |

90/0 |

1064+532/1064+532 |

NCPM SHG @ 1064 nm, T=150° C |

4-LBO-3315-2 |

|

20 |

90/0 |

1064+532/1064+532 |

NCPM SHG @ 1064 nm, T=150° C |

4-LBO-3320-0 |

| 5x5 |

15 |

42.2/90 |

1064+532/355 |

THG @ 1064 nm, Type II |

4-LBO-5515-0 |

|

|

90/11.6 |

1064+532/1064+532 |

SHG @ 1064 nm, Type I |

4-LBO-5515-1 |

LBO crystals for Yb:KGW/KYW lasers

Clear Aperture, mm |

Length, mm |

Orientation Θ/φ, ° |

AR coatings S1/S2, nm |

Application |

Product ID |

| 6x6 |

0.9 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-0609-2 |

|

1.9 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-0619-2 |

|

2.8 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-0628-2 |

|

3.7 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-0637-2 |

| 8x8 |

0.9 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-0809-2 |

|

1.9 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-0819-2 |

|

2.8 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-0828-2 |

|

3.7 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-0837-2 |

| 10x10 |

0.9 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-1009-2 |

|

1.9 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-1019-2 |

|

2.8 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-1028-2 |

|

3.7 |

90/13.8 |

515+1030/515+1030 |

SHG @ 1030 nm, Type I |

4-LBO-1037-2 |

Disclaimer

Laser induced damage threshold (LIDT) measurements are performed on actual components produced by Altechna. Individual component’s LIDT depends on multiple parameters (substrate material, polishing batch, coating batch, storage conditions, etc). Damage threshold value reached for above individual components should be used for reference only but it is not guaranteed for all optics. LIDT reports for a coating batch can be ordeder upon request.