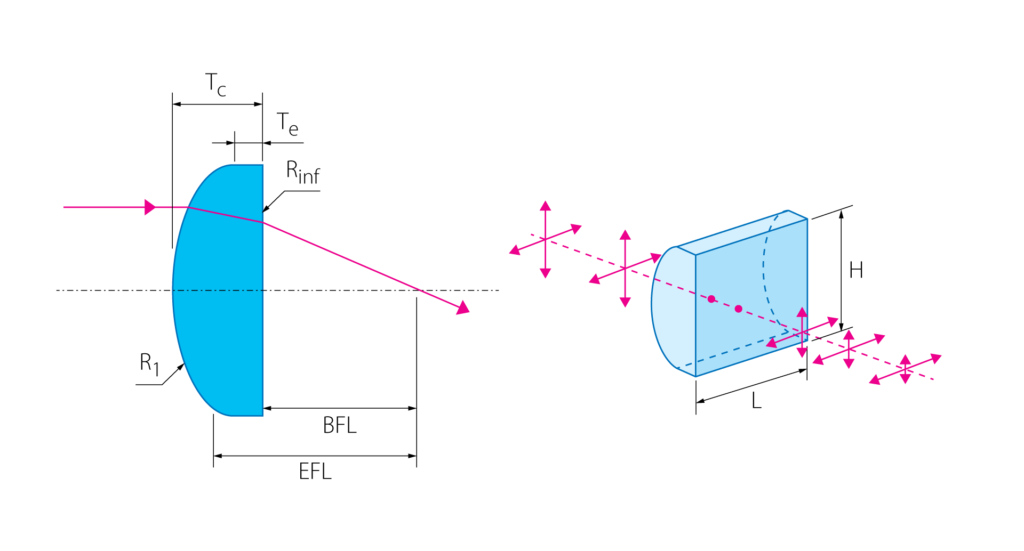

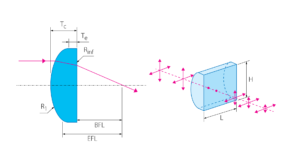

Positive Cylindrical lenses

Positive cylindrical lenses are used to focus light into a thin line for effective harmonic generation in nonlinear crystals, for laser scanners, spectroscopy, dye lasers, acousto-optics and other applications. They are ideal for the circularization of diode laser outputs, energy collection for linear detectors, or coupling to a slit input.

The most common materials used for these lenses are BK7 and UVFS. However, UVFS has various grades and a specific grade of glass should be chosen for specific applications. If you have doubts about which type of glass is best for your application, contact us for advice.

Cylindrical lenses are typically coated with e-beam technology that can reach a reflectivity of R<0.2% per surface, but for more demanding applications sputtering technology is used to achieve a reflectivity of R<0.1%.

We have a team of experienced coating engineers and metrology capabilities to prototype and transfer your idea into a well-defined production process. Feel free to reach out to us for more information or any inquiries you may have at: [email protected]. We’re here to assist you!

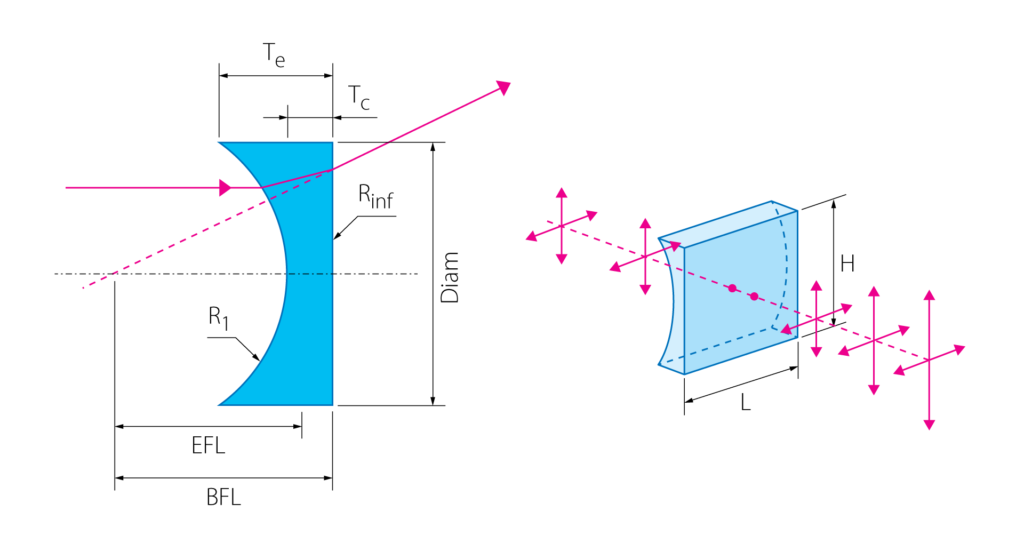

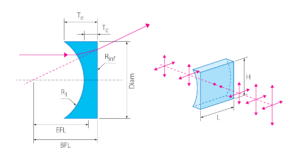

Negative cylindrical lenses

Negative cylindrical lenses expand a beam along one axis. A typical application for such lenses is beam shaping. An anamorphic shape for an image/beam can be achieved by using a pair of cylindrical lenses, making these an irreplaceable tool for the circularization of diode laser output beams.

The most common materials used for these lenses are BK7 and UVFS, but it should be taken into account that a specific grade of glass should be chosen for specific applications. If you have doubts about which type of glass is best for your application, we are here to advise you.

These lenses are typically coated with e-beam technology and a value of R<0.2 % can be reached per surface. For more demanding applications, however, lenses can be coated with sputtering technology to achieve a value of R<0.1 %.

Contact us for help with your challenge. We have a team of experienced coating engineers and metrology capabilities to prototype and transfer your idea into a well-defined production process.