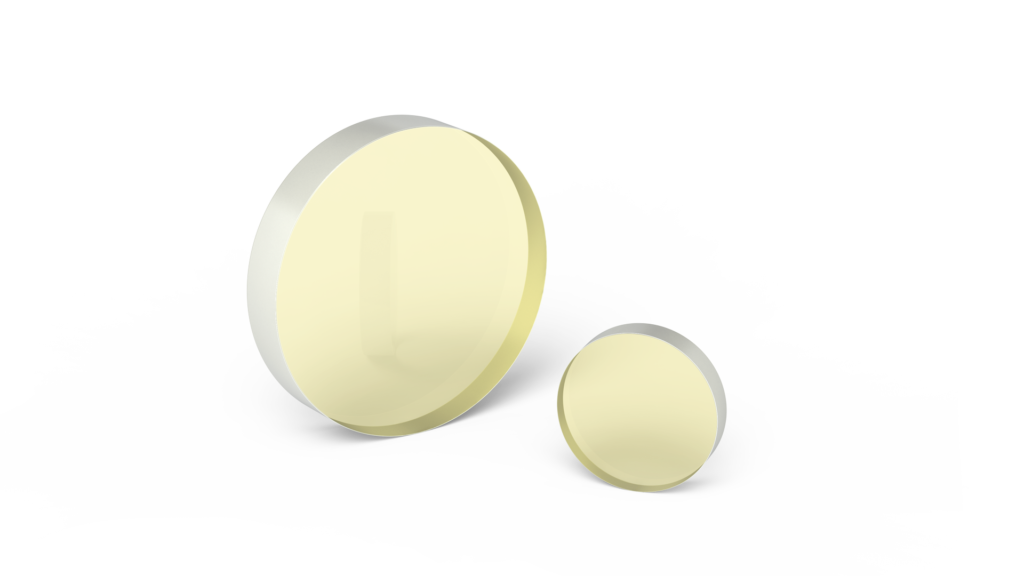

Protective windows for high energy lasers

Protective windows are the front part of every laser-cutting and welding system and these are crucial for ensuring the reliable and uninterrupted operation of laser systems.

Protective windows for high-energy lasers are designed to be used as a safeguard for the more expensive optics inside the laser cutting head. They are placed as the last optics before the work piece.

Installing these means that debris, fumes, and splashes are deposited on the protective windows for high-energy lasers instead of the expensive focusing lenses. Eventually, these consumable windows must be changed, once debris starts damaging the dielectric coating. Our protective windows come packed individually for fast replacement.

Our experience has led us to achieve spectacular results with high-power systems. We use high-quality substrate materials and top-quality coatings for our AR coated windows. Our designed and in-house made coatings provide two main benefits:

- They prevent any backscattering and reflections during the processes

- They increase process efficiency by minimizing reflective losses from windows

In general, this allows us to offer items that can withstand power rates exceeding several kW. Some of our most popular protective windows are ready off the shelf. If not, Altechna can prepare AR coated windows according to the needs of your system.

Contact us for more information: [email protected]