Please note that this website uses cookies. By clicking “Agree” or continuing to browse, you agree to the use of cookies. You can revoke your consent at any time by changing your web browser settings. More about cookies – Cookie Policy.

2 μm Laser: From Research to Industrial Applications

2 μm: From Research to Industrial Applications

By Laurynas Šatas, 2020

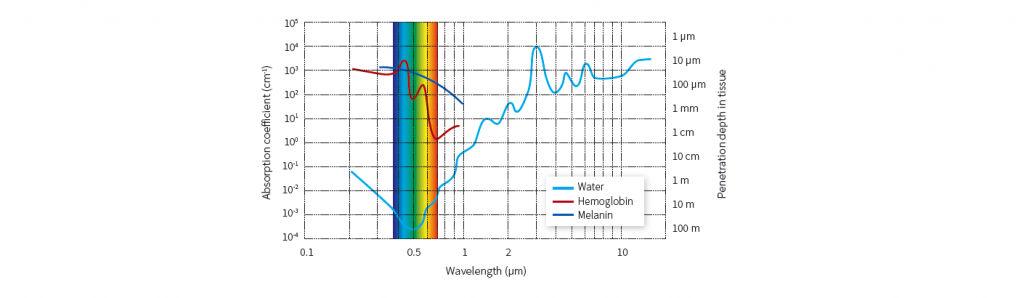

Over the past few decades, lasers have become an increasingly crucial tool for multiple applications. By selecting the right tool and optimizing its parameters professionals can cover wide range of different technological tasks with optimum efficiency. Lasers operating at the wavelength range of 2 μm is highly demanding due to its unique properties. Water absorption increases steadily from 1.2 to 2.9 μm, resulting in wavelengths of around 2 μm still belonging to the so-called “eye-safe” region – with water making up around 70% of corneal tissue. Through falling within this region and still being at a suitable atmospheric window, lasers operating at the wavelength of 2 μm enable an entire range of applications and opportunities for free-space communication, remote detection (for atmospheric absorbers: H2O, CO2, N2O, etc.) and spectroscopic advances in environments that cannot be isolated from people.

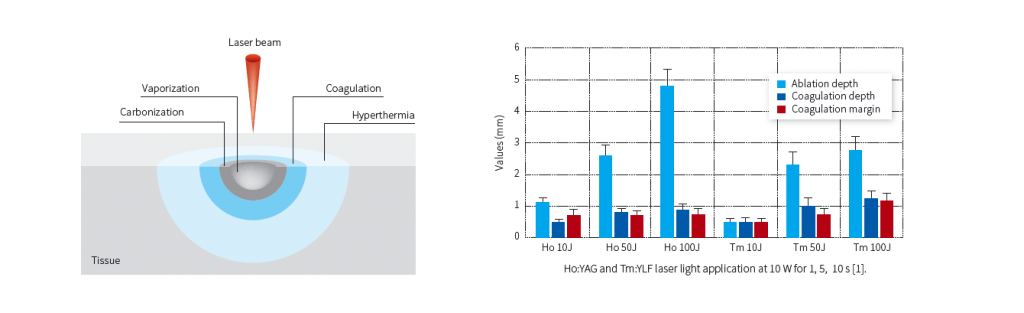

While these lasers are considered eye-safe, the same water absorption line located at these wavelengths makes such lasers some of the preferred tools for precision surgery. With direct or endoscopic medical applications, there are only two critical parameters that matter: coagulation and ablation depth. Small coagulation zones help doctors to contain bleeding and significantly improve procedural quality, whereas large ones can disturb the functionality of tissue. Precise control of ablation depth and affected zones is highly important in allowing professionals to ensure a high level of accuracy in precision surgery.

It has been shown that the actual wavelength is also important for the ablation of biological tissue. A comparison between two of the most popular laser systems – Ho:YAG and Tm:YLF – suggests that the sweet spot is located somewhere around 2090 nm. At the same average powers, Ho:YAG lasers show almost twice the ablation depth while maintaining smaller coagulation zones than Tm:YLF lasers. In addition ability of Ho:YAG lasers to work in different regimes (CW and Q-switched with electrooptical or acousto-optical modulators [4]) and tune wavelength from 2090 to 2123 nm leads to extraordinary process control.

Figure 1. Single-spot experiments (fiber-tissue distance d=5 mm) on porcine liver tissue using Ho:YAG and Tm:YLF laser in CW mode (P=10 W, t=1, 5, and 10 s). Mean and standard deviations of ablation depth, axial coagulation depth and width of the radial coagulation edge are shown [1].

Figure 2. Absorption and penetration depth in water and other biological tissue constituents for different wavelengths [1].

High-importance applications also include defense and security fields. IR guided missiles were responsible for 90% of damaged planes in conflict areas around the world over the past 20 years. Direct infrared counter measure (DIRCM) systems serve a crucial role in protecting planes from these heat-seeking projectiles. Therefore it is crucial to have a compact and reliable DIRCM system as it can save a plane and the lives of its crew. These systems come in two types: one operates in the first atmospheric window at wavelengths of around 2 micrometers, and a second is designed for the second atmospheric window of 3-5 μm. The latter is typically a high-complexity hybrid laser system containing a thulium-based diode-pumped fiber laser, Ho:YAG in a solid-state and a zinc germanium phosphide (ZGP) optical parametric oscillator [3]. Challenges with DIRCM systems can be properly addressed only through multiple stages of optical pumping, which result a bulky and expensive system.

Dielectric coatings

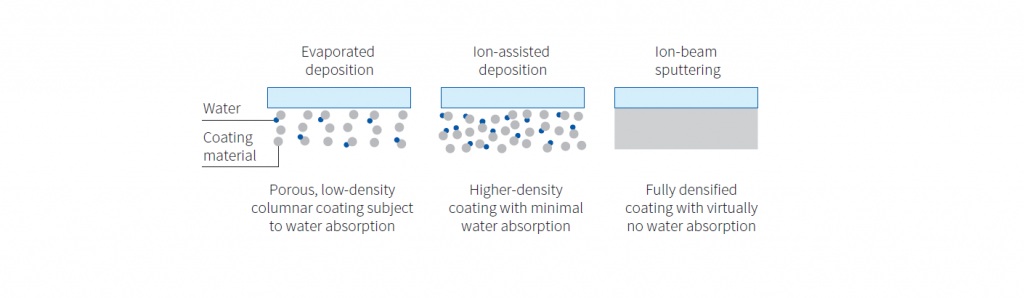

Interference coatings are constituents that make optical glass into a low-loss window or laser mirror. Depending on the technology used, coating density can range from highly porous to near-as-bulk. In typical NIR nanosecond applications, it is known that more porous coatings are capable of surviving higher energy densities due to having lower stresses. However, in the spectral region where water absorption is critically important, technologies that are highly functional at 1 μm range do not work at 2 μm as well.

A great rule of thumb when considering best optical coatings at 2 μm range is that the higher the coating density the better. Ion beam sputtering and magnetron sputtering technologies are perfectly suited for this through their ability to achieve the highest coating density and degree of precision. Such coatings are not affected by environmental humidity and are free of H2O content within layers. While in some systems components can be sealed off and protected with inert gases, coatings based on sputtering technologies are the only viable option for the operation under atmospheric conditions.

Figure 3. Evaporative deposition produces porous coatings that can absorb moisture, while IAD reduces this problem and IBS completely eliminates it [5].

Challenges

Depending on the application, there can be several different challenges that laser engineers need to address in the development of new-generation laser sources. Stability, beam quality, and certain power levels are key to most remote-sensing or medical applications, while in the defense market it is size, weight, and efficiency that are even more important and difficult to achieve. For a system to become smaller, lighter and more powerful, it means having a narrower spot size and higher fluencies that optical components must be able to withstand. The lifetime and stability of the weakest component will, therefore, define the longevity of the system itself, with the need to give special attention to the production of each individual component.

Continuous irradiation going through a volume of amorphous glass will run into all the impurities and potential absorbers typical for the actual wavelength. In the 2 μm region, the biggest foes are OH absorption bands, which cause local heating of glass that results in thermal lensing and distortions. This well-known issue is easily resolved with the right selection of infrared-grade fused silica (OH concentration <5 ppm) or calcium fluoride optics.

Altechna solution for 2 μm applications

The development of new-generation optical components capable of managing today’s challenges is a complex process. It involves more than one discipline, ranging from material science to engineering. Altechna engineers have identified several technological bottlenecks of laser systems that work in the region around 2 μm and prepared a full industrial solution. High-quality optical components for laser resonators and delivery optics are now available in prototyping quantities, as well as for mass production.

Beam steering optics

- Any common infrared-grade fused silica (Corning 7979®, Infrasil®, etc.)

- Excellent accuracy for ROC and centering tolerances

- Dielectric coating sputtered with metal oxides

- LIDT: >30 J/cm2 @ 2090 nm, 10 ns*

High LIDT Ho:YAG laser crystals

- Ho3+ concentration: 0.5 – 2%

- Surface quality: 10-5, S-D

- Surface flatness: <λ/10 @ 632.8 nm

- Parallelism error: <5 arcsec

- LIDT: >30 J/cm2 @ 2090 nm, 10 ns*

High LIDT cavity mirrors

- Any common infrared grade fused silica (Corning 7979®, Infrasil®, etc.)

- EM optimization

- Low-loss design

- Dielectric coating sputtered with metal oxides

- LIDT: >30 J/cm2 @ 2090 nm, 10 ns*

*NOTE: No damages were found while testing, therefore, LIDT value could not be evaluated. LIDT value should be higher than the maximum fluence value used in the test. This fluence value is written in the specification table [6].

References

[1] Frontiers in Guided Wave Optics and Optoelectronics, Book edited by: Bishnu Pal, ISBN 978-953-7619-82-4, p. 674, February 2010, INTECH.

[2] Antipov, O., Zakharov, N., Fedorov, M., Shakhova, N., Prodanets, N., Snopova, L., Sharkov, V. & Sroka, R. (2011). Cutting effects induced by 2 μm laser radiation of cw Tm:YLF and cw and Q-switched Ho:YAG lasers on ex-vivo tissue. Medical Laser Application, 26, 67–75. doi: 10.1016/j.mla.2011.02.004.

[3] Hemming, A., Richards, J., Bennetts, S., Davidson, A., Carmody, N., Davies, P., Corena, L., Lancaster, D. (2010). A high power hybrid mid-IR laser source. Optics Communications, 283 (20), 4041–4045. doi: 10.1016/j.optcom.2010.05.078.

[4] Wang, Y. P., Dai, T. Y., Wu, J., Ju, Y. L., & Yao, B. Q. (2018). A Q-switched Ho:YAG laser with double anti-misalignment corner cubes pumped by a diode-pumped Tm:YLF laser. Infrared Physics & Technology, 91, 8–11. doi: 10.1016/j.infrared.2018.03.020.

[5] Trey Turner, Laser Focus World (2011), Thin-film coatings: Military laser technologies challenge optical-coating manufacturers, <https://www.laserfocusworld.com>.

[6] Tested at Lidaris, JSC.